The Project

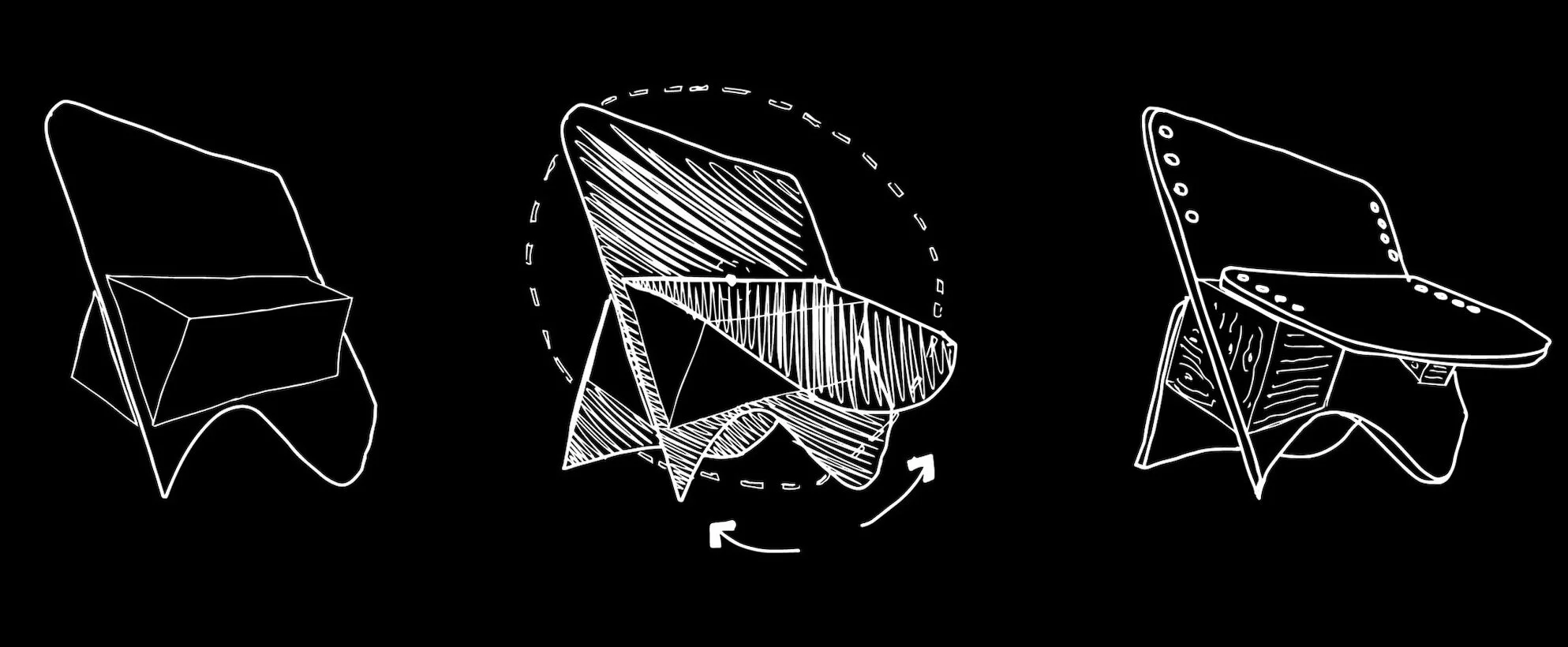

Traditionally, a running mold for plaster consists of a running a blade profile repeatedly over a fixed linear path. The result is a plaster piece with a fixed profile. Leveraging on the range of a six-axis robot, the goal of the project was to expand the limits of this traditional tool. This workflow aimed to create a polymorphic tool with three blade-profiles activated by the rotation around the central pivot point. This allowed the plaster piece to have a customizable and alternating profile.

This project was made in collaboration with Twisha Raja, Maria Vlachostergiou and Peijing Xu.

The Tool

The tool was designed using Rhino3D and then made using a laser cutter. The first tool that was created used triangular wooden blocks to support the blades. This proved too unstable, which resulted in the vibration of the blade. Therefore, the final tool was changed and constructed using a variety of laser-cut plywood triangles supporting the blade along the entire length of the tool.

Tool Development

Tool 1

Tool 2

The Process

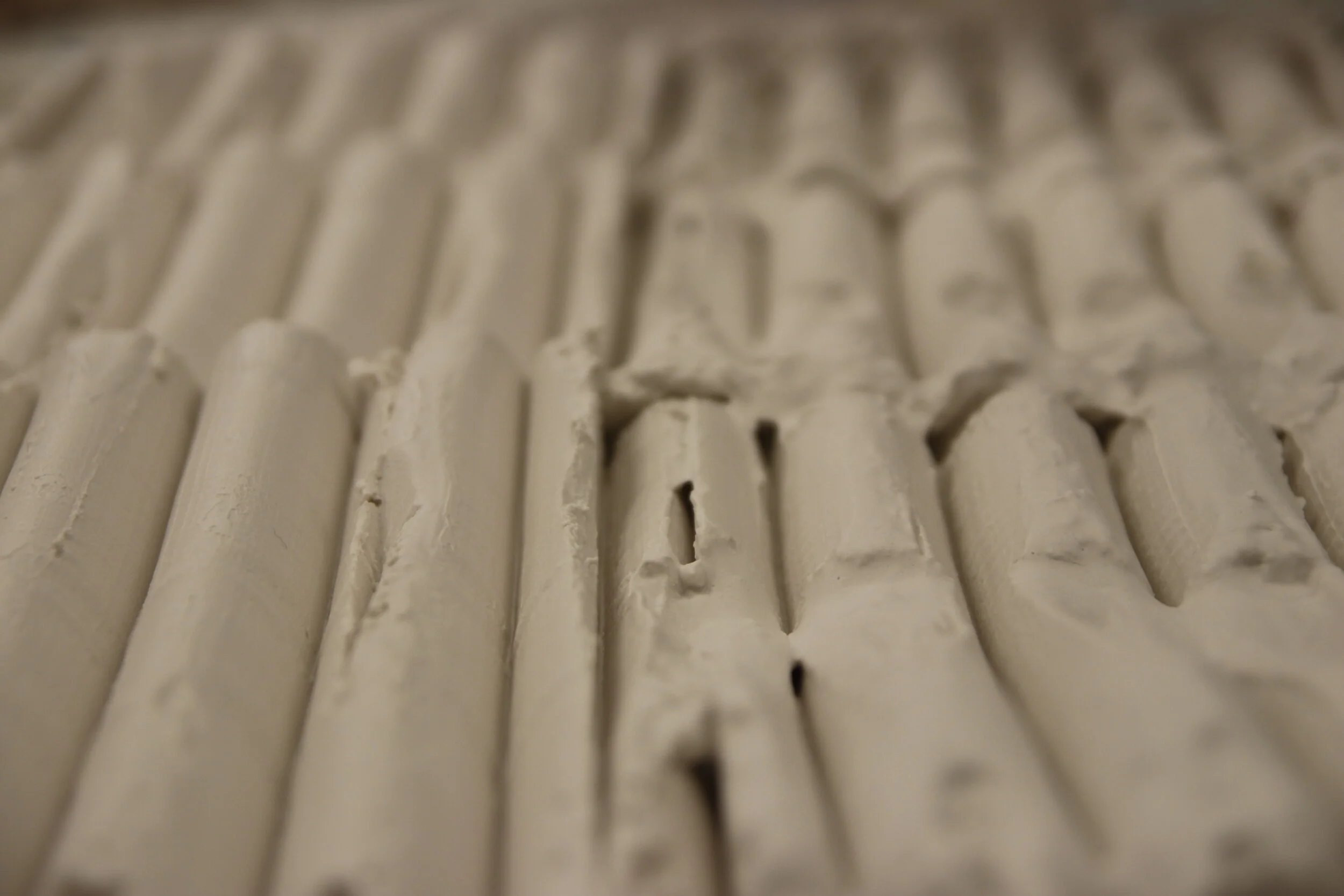

The ABA robot was programmed to follow a specific path which was created by assigning a series of target locations and angles along the length of the piece.

Modeling

A model of the output profile was modeled using grasshopper and Rhino3D by running the selected blades at the target angles along the robot’s path.

Final Process

Final Product

Skills Developed

Grasshopper, Rhino, ABA robot handling, laser cutting, woodworking (including cutting and drilling), plaster mixing and working