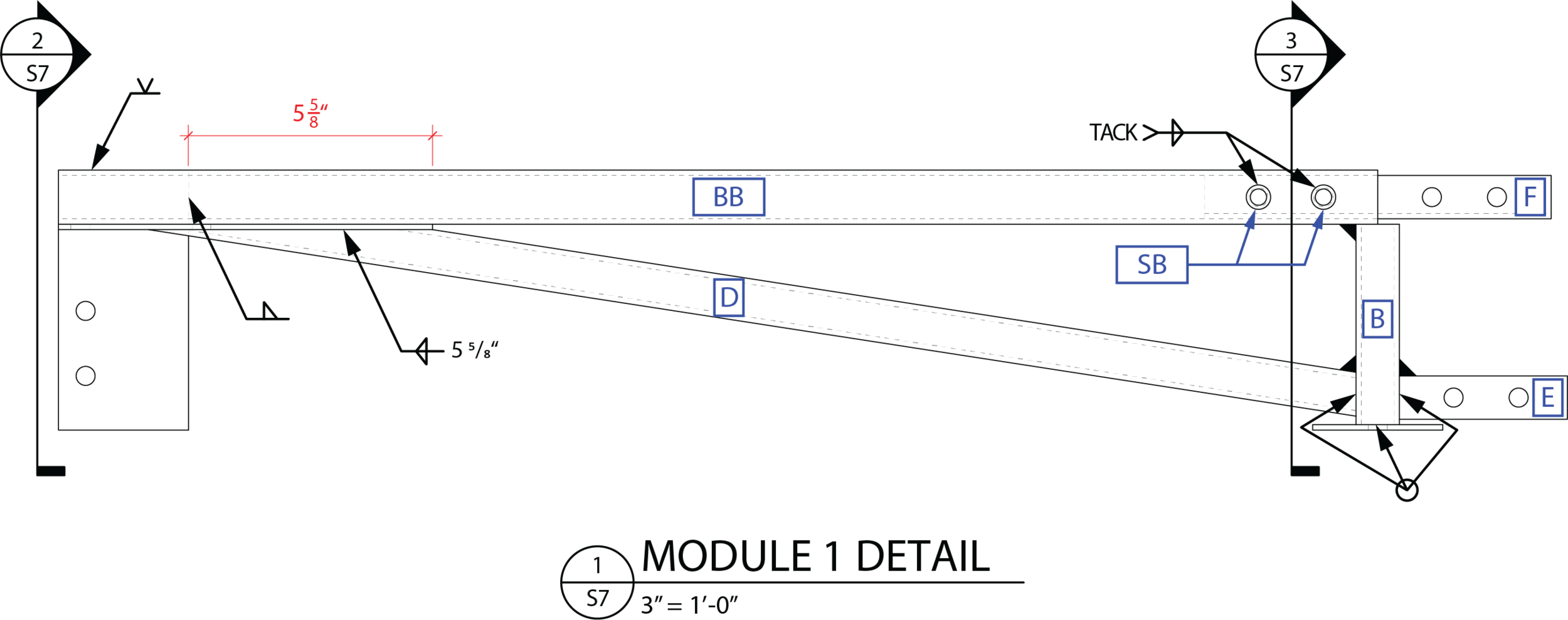

Elevation view of the side and end of final bridge design.

The Project

This project was done in collaboration with Paul Anderson, Taylor Brown, Rachel Clapper, Emma Farrell, Logan Pierce, Simone Stein, Tessa Weeden and Yuneil Yeo. The assignment was to design and manufacture the lightest, fastest to assemble, most economic and environmentally-friendly steel bridge spanning 20’ and able to carry a load of 2500lb.

The Design

The approach that was taken was to use the largest number of prefabricated assemblies or “modules” that could then be rapidly connected during the timed building competition. This would both decrease the build time and the weight, since we had to comply with the maximum dimensions allowed for welded pieces, which required a small truss depth.

Basic Loading Conditions

We used these basic loading conditions to make sure we were designing the bridge to hold the maximum forces created.

Putting together all the loading conditions, we were able to determine the shear and moment diagrams for our system and use those to design members that would decrease the deflection when loaded this way.

The Design Process

The shape of the bridge was designed first, and the vertical forces on each member were calculated using both hand calculations and RISA. The required member sizing was then determined using hand calculations, and the choice of appropriate steel member shapes, sizes and thicknesses was made. The group decided to use hollow square members that would decrease the weight and make it easier to connect. The hollow members also allowed our modular connections to use telescoping members, which increased the stiffness of the overall design since we were able to weld the connecting pieces and only use bolts to hold the two members in place.

Animate simulation of the telescoping connections for the modules of the truss.

Results

Total Build Time: 35 min

Weight of bridge: 390 lb

Total Material Cost: $452

Total Fabrication Cost: $236

Total cost: $688

Total Fabrication Time: 270 hours

Skills Developed

Fabrication

Cutting, drilling, extensive welding, sand plastic, sanding

Design & Analysis

Rhino, AutoCAD, RISA

Collaboration

Team work, working with tight schedules, working with multiple fast deadlines, efficient and effective communication with team and professors in and outside of the workshop, workshop safety procedures